Wheelset Presses

Innovative technical solutions. MAE has been developing and supplying assembly presses for wheelsets of rail vehicles for over 70 years. Whether you need to press wheels, brake discs or gearboxes, whether high-speed trains or street cars, we have the right solution for you.

On this page:

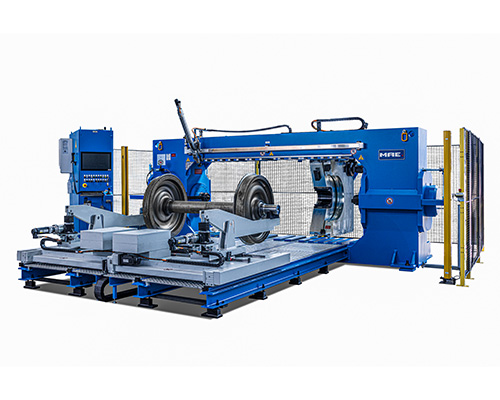

Wheelset press RADS

Efficient assembling and disassembling wheelsets

You want to assemble and disassemble wheelsets of rail vehicles? Our horizontally operating double-cylinder wheelset presses of the RADS series are the specialists for pressing wheelsets for rail vehicles.

RADS video - short presentation

Explore the advanced RADS wheelset press!

Click now to watch the video for the short presentation,:

You are currently viewing a placeholder content from Youtube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationAll videos are available on our Youtube channel.

Advantages & Product Details

Advantages:

- High productivity due to completely automated pressing process

- Various loading and unloading solutions

- High quality and productivity guaranteed by means of optimally matched accessories

- Pressing tools, easily displaceable and mounted in a pollution free manner

- Exceptionally energy efficient due to patented demand-controlled hydraulic system

- A certified, highly practice-oriented safety concept

Product details:

- Pressing forces from 2,000 to 6,300 kN

- Shaft lengths from 400 to 3,200 mm

- Wheel diameter from 400 to 1,500 mm

- Unit weights up to 8,000 kg

Structure of our wheelset presses

Extremely space-saving – a big plus of the patented RADS wheelset presses. The innovative basic concept of the machine also offers you:

- High stability due to integral frame construction

- Comfortable pressing on and off is possible thanks to the large basic tools mounted directly in the press frame – even for critical wheelsets with tight spaces

- Very good ergonomics

- Optimal accessibility of the toolroom; a system of interlocking tools guarantees easy retooling

Different methods are used for pressing:

- Conventional pressing

- Pressing with high pressure support

- Positioning against a fixed stop or free

- Pressing cylindrical and conical seats

A variety of wheelsets are assembled, disassembled or maintained with wheelset presses by MAE:

- Trailing wheelsets with and without brake disc

- Drive wheelsets for railcars

- Wheelsets for locomotives with gearbox and/or with traction motor

From street cars and high-speed trains to three-phase electric locomotives: wheelset presses from MAE![]() are suitable for all wheelset designs.

are suitable for all wheelset designs.

Contact person for RADS series

RACOS - Software

Modern measurement and control technology

Process reliability, accuracy, user-friendliness; these are important characteristics of the measuring and control technology of a wheelset press. We addressed these issues from the very beginning. Our answer to these challenging tasks: RACOS – with its powerful computer and a freely programmable measurement technology, we have set new standards for the entire railway industry, that make your processes safer and more reliable.

The process: basic functions

- Industrial PC A powerful industrial PC is the core of the system and guarantees smooth operation at all times.

- Collecting process information Detailed process information and encoder signals and applied forces are combined to optimize the process.

- Freely programmable sequence RACOS controls the automatic movement of all drives in the freely programmable sequence harmonizing press cylinders movements with tool adjustments and loading technology.

- Process data at one glance The large touchscreen LC display shows the process clearly and detailed guaranteeing a highly convenient operation.

- Microsoft Windows Comfortable Windows user interface offers the familiar access and is easy to work with.

- Optimally connected An Ethernet connection with interfaces for customer databases enables fast and smooth data export of the recorded wheelset data.

- Remote maintenance Worldwide a direct connection. MAE

systems are connected to the MAE

systems are connected to the MAE Service Department via a network connection or mobile data transfer. For diagnosis and updates: our experts can intervene directly.

Service Department via a network connection or mobile data transfer. For diagnosis and updates: our experts can intervene directly.

The software: RACOS highlights

- Curve evaluation The central quality feature for the pressing process is the force-path course shown in real time on the display. The RACOS system offers an utmost flexible way of parameterizing process defining limit data set down in the specifications of the wheelset manufacturers and the innumerable regulations and criteria worldwide, and evaluating the force curve accordingly, while directly displaying the pertinent regulations.

- Measuring head With the universal measuring device you can easily record all geometric data of the wheelset relevant for the pressing process. The axial positions of wheel and brake disks, gearboxes, shaft reference surfaces and seat diameters on the wheelset shaft are taken into account. You can measure axial and radial run-out of the shaft, wheels and brake disks while the wheelset is rotated. The measures are taken by tactile or laser measuring heads – depending on the task.

Contact person for RACOS

Did you know...

…that our wheelset presses only consume about as much electricity as an electric kettle?

The careful use of resources is more important today than ever before. We have therefore optimized our wheelset presses so that they consume significantly less electricity and hydraulic oil than comparable machines. This is how the acquisition of a MAE wheelset press usually pays off after a very short time.

You would like to learn more? Contact us.

Additional equipment

As individual as your requirements

Do you need special equipment, tools and services for your wheelset press? In addition, are you thinking about customized components? We will find the optimal solution for your needs; from special tools to customized software. Contact us.

Additional equipment at one glance:

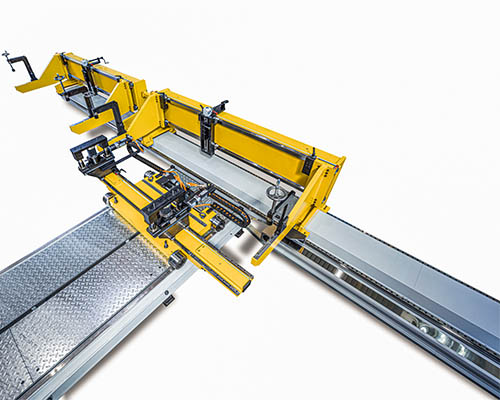

Pre-assembly stands

A separate workstation for pre-assembling wheels and brake discs should be available. It relieves your employees and increases their productivity: parallel to the pressing process, they can prepare the next wheelset. We offer two basic types of pre-assembly stands:

- A simple version with one workstation.

- A double pre-assembly stand: employees pre-assemble wheels and shafts at one station while loading or unloading at the second.

High pressure pumps

We offer manually or automatically operated high-pressure pumps and appropriate hoses, as well as quick-change connecting adapters for creating a pressurized oil lubrication between the shaft and wheel hub to facilitate the pressing-off procedure. Drip pans, optimized hose routing and a closed machine frame reduce contamination and the risk of accidents.

Tools and engineering

The wheelset press is a standard product, isn’t it? Of course, it is as far as the basic concept is concerned. The d are as manifold as the rail vehicles themselves. To turn the wheelset press into a highly adaptable machine, we design the tools according to your specifications: once the pressing force has been decided on the basic inserts are defined, then a combination of interlocking wheelset specific tools are designed and produced which enable a quick changeover for your production.

That way we can also equip existing wheelset presses with additional tools, should you wish to extend the range of your production.

Transportation

- Manual wheelset transport carriage

The wheelset transport carriage can significantly improve the efficiency of the wheelset press by reducing cycle times. It simplifies the handling of the wheelsets, especially when entering the press. Even wheelsets with gearboxes can be moved easily this way. - Wheelset manipulator MAE

MoviS

MoviS

The MoviS wheelset manipulator can pick up entire wheelsets or shafts from the floor or a pre-assembly stand, transport them to the wheelset press for the pressing procedure, and afterwards place them in front of or behind the press. If desired, all movements can also be completely automated. - Heavy duty wheelset transport carriage MAE

MoGiS

MoGiS

The MoGiS heavy-duty wheelset transport carriage facilitates the handling of heavy wheelsets with weights of up to 8 tons. - Overhead crane

Do you want your wheelset press to be independent of the availability of a big overhead crane? Use a small gantry crane exclusively for your wheelset press and adapted to your space limits! Three individually or synchronously operated hoists transport wheelset shafts and wheel and brake discs to the pre-assembly stand. You can also pick up and set down completely assembled wheelsets at any position within the crane’s work area.

Contact person for additional equipment

Have you already had an insight?

In the series of manual straightening presses?

Or do you want more information about workpieces & applications?