Automatic straightening machines

Increasing production rates demanding tighter cycle times or a shortage of skilled staff can force you to automate your production process. Whether manually loaded or completely automated, our automatic straightening machines fit smoothly into your production process and make you even more efficient. You can always rely on our modular design concept, but are also prepared to design a “one-of-a-kind” solution for you.

On this page:

M-AH Automatic Straightening Machine

Our series with a pivoting ram plate

The world’s first straightening machine with a patented electro-mechanical drive continues to fascinate with its comprehensive concept. Depending on your application you can straighten round and flat workpieces, and also parts with a complex geometry, precisely with our M-AH, if needed completely automated.

M-AH Video - Short Presentation

Dive into the efficient world of the M-AH series with the short video presentation!

Ready… click:

You are currently viewing a placeholder content from Youtube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationAll videos are available on our Youtube channel.

Advantages & Product Details

Advantages:

- Low energy consumption because of the almost inertia-free, dynamic cam drive and optimized leverage of the pivoting ram plate

- Maintenance-free bearings of the ram plate for trouble-free continuous duty

- Improved operator safety and long-term backlash-free functioning due to integrated counterweight

- The wide opening ram plate enables a straight passage of the workpieces guaranteeing an easy, cycle-time reduced integration into your production line

- Particularly compact and space-saving design

Product details:

- Straightening forces from 60 to 2,000 kN

- Workpiece lengths from 30 to 3,000 mm

- Workpiece diameters from 2 to 300 mm

- Straightening accuracy down to 0.01 mm

Contact person for M-AH series

Automatic Straightening Machine ASV

Our series with movable press frame

Explicitly tailored to the requirements of long part manufacturers, we have developed our patented ASV series. It offers a proper straightening strategy for diverse workpieces e.g. guide rails, piston rods, universal beams and girders, pipes and tubes of different kinds or large steel bars. With our ASV series we can proudly claim to possess the proven concept for straightening the largest workpieces in the world.

Video - Short Presentation

Discover the ASV, our efficiency-boosting innovation: Featuring a patented hydraulics concept for low energy consumption and minimal maintenance. The compact moving frame design and rugged construction ensure durability even in demanding environments.

Your click on the video brings the ASV action:

You are currently viewing a placeholder content from Youtube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationAll videos are available on our Youtube channel.

Advantages & Product Details

Advantages:

- Low energy consumption and almost maintenance free because of the patented hydraulic system

- The continuous straightening method enables a fast, effortless changeover

- The moving frame concept guarantees a space-saving installation

- Particularly robust design for use in demanding environments

- Economical even with small batch sizes

Product details:

- Straightening forces from 400 to 40,000 kN

- Workpiece lengths from 300 to 30,000 mm

- Workpiece diameters from 15 to 800 mm

- Straightening accuracy down to 0.01 mm

Contact person for ASV series

Did you know...

…that we also offer our machines with the appropriate conveying systems?

The straightening process itself is one matter, the question of how the workpieces enter and leave the straightening machine is another. In addition to manual loading and unloading, we offer conveying systems for our straightening machines tailored to your needs. Just contact us.

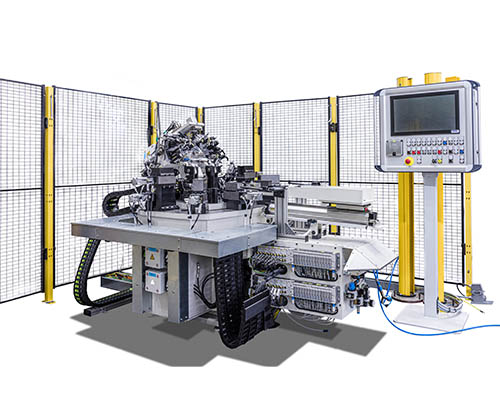

Automatic Straightening Machine M-ASRU

Our series for straightening three-dimensional workpieces

Components do not always require one-dimensional straightening operations to correct form defects. Particularly with complex components such as welded or cast parts, multidimensional corrections may be necessary to achieve the desired result. With our M-ASRU series, we offer a machine concept for straightening three-dimensional parts. To this end we rely on our modular machine concept which is flexible enough to recombine it to your particular straightening task.

Advantages & Product Details

Advantages:

- Straightening in three dimensions due to variable straightening arrangement

- High cost-effectiveness through use of standard machine components

- Individual adaptation to the respective straightening task

Product details:

- Straightening forces up to 1,000 kN

- Straightening accuracy down to 0.05 mm

Contact person for M-ASRU series

RICOS - Software

Our straightening and measuring control

The straightening computer is the brain of our automatic straightening machines and therefore of crucial importance for the performance of these systems. Even the standard configuration of our RICOS straightening control is impressive. MAE![]() systems have a sophisticated computer architecture with separate processors for the straightening sequence and the visualization, as well as a field bus connection between machine and PLC. With the large-surface TFT touchscreen display and the Windows user interface, you can enjoy optimal operating convenience working with our straightening machines.

systems have a sophisticated computer architecture with separate processors for the straightening sequence and the visualization, as well as a field bus connection between machine and PLC. With the large-surface TFT touchscreen display and the Windows user interface, you can enjoy optimal operating convenience working with our straightening machines.

The straightening process: Basic functions

- Self-learning stroke depth control

Optimize cycle times, reduce number of strokes, minimize workpiece stress and compensate for tool wear: With RICOS, you control your straightening process precisely as you want it. - Freely configurable straightening sequence

With pre- and finish-straightening functions. They straighten either in relation to the total length or to individual sections. - Freely selectable reference base

You have the choice: either straighten relative to the peaks or to two pre-selected measurement points. - Batch statistics

In addition to the standard workpiece statistics, you would like to receive a detailed evaluation of single batches? RICOS provides you with every statistics you need. Curvature data are presented in histograms and tables. You can check the workpiece quality before and after the straightening process in detail. - Remote maintenance

A direct line worldwide. MAE systems in facts: straightening control, drive system and PLC are connected to the MAE

systems in facts: straightening control, drive system and PLC are connected to the MAE Service Department via a network connection or via mobile data. Whether diagnosis or update: our experts can intervene directly.

Service Department via a network connection or via mobile data. Whether diagnosis or update: our experts can intervene directly. - Automatic measuring equipment capability test

The accuracy of the measuring equipment used in straightening machines must be verified regularly; this is the only way to ensure process capability. RICOS automatically performs the series of measurements required for the measurement equipment capability test with all movement sequences and documents the results in accordance with the specifications of the relevant industry standards. - Determine workpiece shape defects

1,000 measured values per revolution, at all measuring points: Shape defects such as ovality or surface roughness are reliably detected. They are calculated, checked for compliance with the tolerance and mathematically separated from run-out errors.

The software: RICOS highlights

- Vector straightening – avoid cracks

You want your workpiece to be bent through only at the measuring points? With highly sensitive workpieces, this can already lead to cracks. RICOS reduces the crack rate: By moving the straightening hammer axially or rotating the workpiece stepwise. Thus, RICOS uses a variety of straightening positions along the workpiece. - Compensation for wear on the centre tips (ZSK)

Run-out caused by the centre tips that actively grip into the centring wholes of the workpiece? Not with RICOS. The control system uses a patented process (ZSK) to detect and largly compensate for these errors with two reference probes on the centre tips. - Varius: the variable straightening strategy

Varius stands for the variable straightening strategy with universal stress profile. This increases performance and accuracy even further. Varius reacts optimally to all existing deviations. The straightening strategy combines the full-length Konti straightening method with the familiar three-point and innovative four-point straightening. - Pressure straightening

Besides the common bending straightening process, RICOS is also suitable for the pressure straightening process. This allows you to efficiently straighten through-hardened or crack-sensitive components. - Profile straightening

Straighten round or completely or partially profiled parts? In one and the same machine? Easily possible with the RICOS control system! - Interactive straightening

RICOS works “far-sightedly”: The control system also takes the position and direction of neighbouring impact vectors into account when calculating the stroke. The result: reduced cycle times, less unnecessary stress. - Data export

ASCII files, Microsoft Excel®, QS-stat® or an Ethernet link: RICOS transfers quality workpiece data in various formats to higher-level computer systems.

Contact person for RICOS

Straightening machine comparison

M-AH |  ASV |  M-ASRU | |

|---|---|---|---|

Straightening forces | from 2 to 1,600 kN | from 400 to 40.000 kN | up to 1,000 kN |

Workpiece lengths | from 30 to 3,000 mm | from 300 to 30,000 mm | up to 2,000 mm |

Parts cross-sections | from 2 to 300 mm | from 15 to 800 mm | ./. |

Straightening accuracy | up to 0.01 mm | 0.01 mm | up to 0.05 mm |

Nothing to straighten?

We also build machines for pressing wheelsets!

With our wheelset assembly presses, the pressing on and off of wheels, brake discs and gears is carried out efficiently, reliably and safely. Interested? Then you have come exactly to the right place: